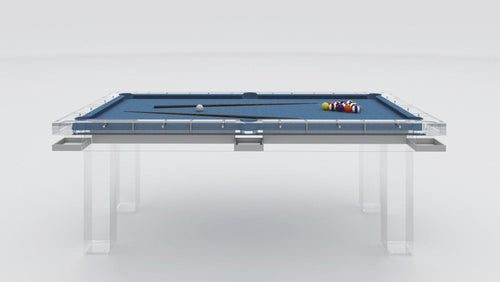

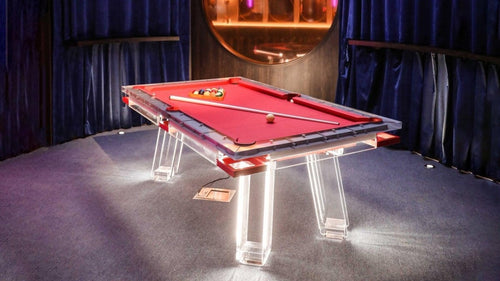

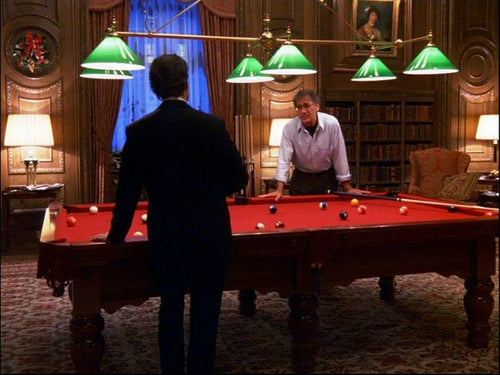

Enjoy our modern designs

Estimated Read Time: 5 mins

The Invisible Risk

In the world of fine furniture, geography is physics. A piece of joinery crafted for the humid air of the English countryside will face a catastrophic shock when transplanted to the arid, air-conditioned interiors of a villa in West Bay or Lusail.

The risk is invisible but destructive. Wood is hygroscopic—it breathes. When a standard mass-produced pool table travels from a shipping container (high humidity) to a Doha Majlis (aggressive climate control), the wood fibers contract rapidly. The result? Warped rails, cracked inlays, and a playing surface that is no longer level.

We do not just export furniture; we engineer it for its destination. Our GCC Climate Stabilization Protocol ensures your investment remains flawless for generations.

The "6% Rule": Kiln Drying for the Desert

The industry standard for drying furniture lumber in North America and Europe is often 8-10% moisture content. For the Gulf region, this is simply too high.

For our Qatar-bound commissions, we utilize a specialized kiln-drying schedule that brings our hardwoods down to a lower equilibrium moisture content (EMC). This creates a "thirsty" timber that is stable and inert. By acclimatizing the wood before we cut a single joint, we ensure that the finished table is already at peace with the dry, cool environment of a modern Qatari home.

Material Selection: Density is Durability

Not all woods are created equal. Soft maples and oaks, commonly used in mid-range tables, are prone to movement. We steer our international clients toward High Specific Gravity tonewoods known for their structural rigidity:

- Gaboon Ebony: Extremely dense and naturally oily, providing a natural barrier against moisture shifts.

- Wenge: A rigid African hardwood that locks into place and refuses to twist.

- Automotive Composites: For our ultra-modern designs, we integrate steel sub-frames and carbon fiber components that are completely impervious to temperature and humidity changes.

The Seal: Locking in Stability

Once the wood is dried and shaped, it must be sealed. We use a proprietary catalyzed conversion varnish—the same finish grade used on the interiors of luxury yachts. Unlike simple wax or oil finishes which allow the wood to "drink" atmospheric moisture, our finish creates a molecular bond with the timber.

This "hermetic seal" ensures that whether your A/C is running at 18°C or your doors are open to the evening breeze, the internal structure of your table remains isolated and stable.

The Guarantee

We are one of the few bespoke manufacturers globally that offers a specific Structural Warranty for the GCC Region. We don't just hope our tables survive the climate; we guarantee it.

When you commission a table for Doha, you aren't buying a product off a shelf. You are commissioning a piece of engineering designed specifically for your longitude and latitude.