Enjoy our modern designs

Over the last hundred years, pool table materials have undergone a remarkable transformation, reflecting shifts in manufacturing techniques, resource availability, player demands, and even cultural tastes. What was once a game played on heavy hardwood frames with natural slate beds has expanded to include a wide range of engineered woods, composite surfaces, advanced fabrics, and eco-friendly finishes. Understanding how these materials evolved sheds light on why today’s tables look and perform as they do. It also underscores what this evolution means for players seeking the best possible billiards experience.

Early 20th Century: Solid Hardwoods and Natural Slate

A century ago, the majority of quality pool tables were crafted from robust hardwoods like oak, maple, or mahogany. These woods offered durability, aesthetic appeal, and the structural stability necessary to support heavy slate beds, which had been the standard playing surface since the 19th century. Slate—quarried from regions with consistent grain and flatness—provided a smooth, level playing field. Sturdy hardwood frames and leg designs ensured these tables would last for decades, if not generations, often becoming heirloom pieces passed down through families.

During this era:

- Slate thickness commonly ranged from 1 to 1.5 inches.

- Fine woolen felt, though relatively fuzzy compared to modern worsted cloth, was considered top-tier.

- Tables were relatively expensive, viewed as luxury items in private homes, social clubs, and upscale billiard halls.

Mid-20th Century: Post-War Resource Shifts and New Wood Options

Following World War II, resource availability changed, and furniture-making industries began exploring more efficient manufacturing methods. Although hardwood still reigned supreme in higher-end tables, more accessible woods and veneered options entered the market to meet growing consumer demand.

This era saw:

- Increased use of veneers and laminated woods to reduce cost without sacrificing style.

- Consistent adoption of slate as the standard, though better finishing techniques improved flatness and smoothness.

- Gradual improvements in cloth quality, with manufacturers experimenting to reduce pilling and slow wear.

Late 20th Century: Engineered Wood and Alternative Materials

As the century advanced, technological innovation influenced pool table construction. Engineered woods like plywood, particleboard, and MDF (Medium-Density Fiberboard) began appearing in lower-priced or mass-produced tables. While these tables couldn’t match the longevity or consistent playability of all-slate models, they offered a budget-friendly entry point for casual players.

Simultaneously, table manufacturers started experimenting with alternative surfaces beyond slate for certain markets, such as portable and recreational use, or children’s tables where cost, weight, and ease of movement were more critical than professional-grade performance. Composite beds made from hard plastics or synthetic materials emerged, primarily in children’s models or portable variants. Though these alternatives never supplanted slate in serious billiards communities, they lowered costs and made pool more accessible.

By the late 20th century:

- MDF and particleboard undercarriages became more common, cutting production costs.

- Synthetic slate alternatives (like “slatron” or fiberboard mixes) were marketed as lightweight and affordable options.

- Cloth manufacturers introduced blends that were smoother and more durable, inching closer to the high-performance worsted fabrics known today.

Early 21st Century: Premium Cloths and Eco-Friendly Innovations

The 21st century kicked off a wave of refined engineering. While slate remained the professional standard, the quality of cloth skyrocketed. Worsted cloth—made from combed, long-staple fibers—offered a faster, more precise playing surface, quickly becoming the choice for professional tournaments and serious home players. This shift paralleled changes in furniture production, as consumers began demanding not just performance, but materials sourced responsibly and designed to last.

Recent decades have brought:

- Advanced synthetic finishes and stains that protect wood, reduce environmental impact, and maintain the table’s appearance.

- More stable engineered woods and composite frames that resist warping over time.

- Cloths engineered with modern textile technology for consistent speed, extended wear, and easy maintenance.

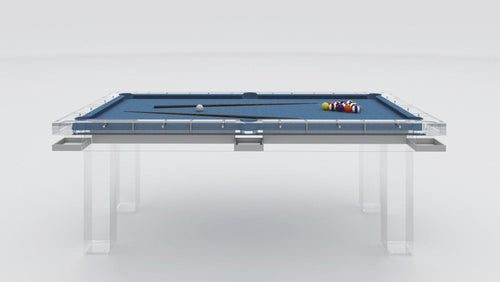

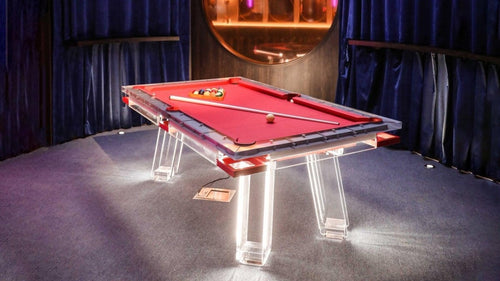

Contemporary Trends: Glass, Acrylic, and Designer Materials

Today, some luxury manufacturers push the boundaries by incorporating unexpected materials like tempered glass and acrylic into their tables. The Arock, a lucite table with an entire base made of lucite, is a standout creation by PoolTablePortfolio that exemplifies modern craftsmanship with a sleek, high-end design. These designs offer a showpiece quality—turning a functional gaming surface into a statement piece of home décor. While still niche, these innovations highlight the flexibility of modern manufacturing.

In premium categories, sustainability has become a selling point. Some companies source wood from responsibly managed forests, use recycled materials where possible, or apply finishes that minimize VOC emissions. Players now have more options than ever, making it easier to align a pool table purchase with personal values and aesthetics.

Key Developments Over the Past Century

- Early 1900s–1950s: Dominance of solid hardwood frames and natural slate beds.

- 1950s–1970s: Introduction of veneered woods and improved adhesives for more affordable models.

- 1970s–1990s: Emergence of engineered woods, synthetic slate alternatives, and better finishing techniques.

- 1990s–Present: High-performance worsted cloth, expanded composite options, designer materials like glass and acrylic, and environmentally conscious sourcing.

What This Evolution Means for Players

The ongoing evolution of materials means players can now choose tables tailored to their exact preferences. High-end purists still gravitate toward traditional hardwood construction and premium slate, knowing they’re getting an heirloom-quality piece. Budget-minded buyers can find more affordable options thanks to engineered woods and synthetic beds. Aficionados of cutting-edge design can even select a glass-topped table that doubles as artwork.

Cloth technology, meanwhile, ensures that even a mid-range table can offer a smooth, consistent roll. With proper care and the right materials, a modern table can achieve a professional playing feel that was once reserved only for top-tier billiard halls.

Looking Ahead

As manufacturing processes continue to improve, new materials and technologies are sure to emerge. The drive toward sustainability, combined with a desire for performance and style, will likely shape the next century of pool table evolution. From humble hardwood beginnings to today’s sleek composites and luxury fabrics, pool table materials have come a long way—and the journey isn’t over yet.

Choosing the right combination of materials today means benefiting from over a century of continuous refinement. It’s easier than ever to find a table that looks incredible, plays beautifully, and stands the test of time.