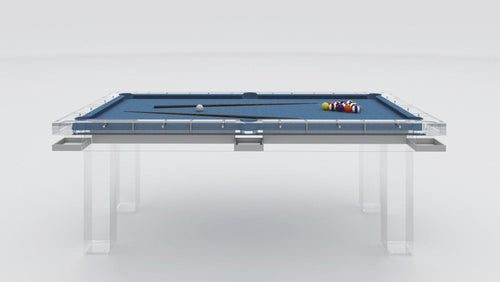

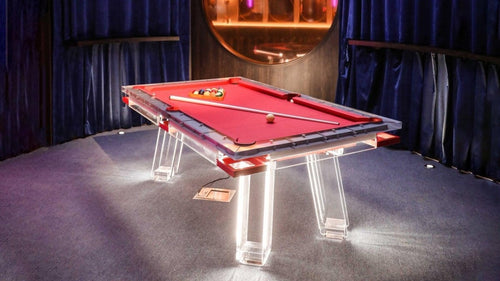

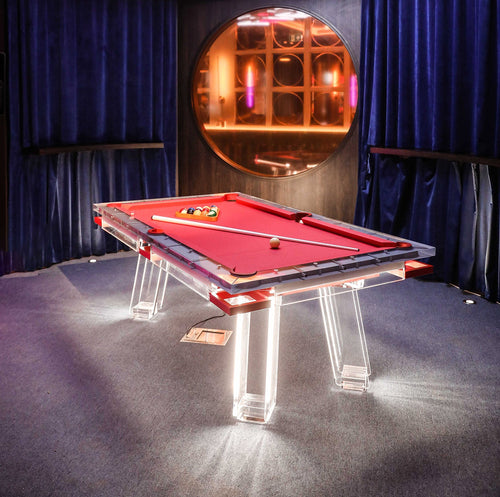

Enjoy our modern designs

Banks running short on one table and long on another isn’t random. It’s the sum of geometry, rubber chemistry, cloth condition, and installation precision. This guide gives you the working theory, the numbers that matter, and the quickest tests and fixes to make a table play the way you want—on purpose.

Quick answer

Cushion nose height: Lower than spec → banks shorter & faster. Higher than spec → banks longer & slower. This one variable explains most “why does this table feel different?” complaints.

Rubber profile & compound: K-profiles (K-66, K-55) and durometer (Shore A) set rebound character. Softer blends feel lively; harder blends return angles crisply but can ring if paired with thin facings.

Cloth, balls & humidity: Clean, dry worsted cloth + polished balls = less friction → shorter, truer banks. Humid/dirty cloth grabs, slows, and lengthens banks—sometimes dramatically in coastal rooms.

Install & aging: Bolt torque, glue bond, facing thickness/hardness, and rail wood condition can simulate “dead” or “springy” rails even when the rubber is fine.

How rail rebounds actually work

Bank shots are not mirror-perfect. The cue ball loses speed and changes spin state on impact. At shallow incidence, the ball sheds little speed and the outbound angle tracks close to geometric predictions. At steeper incidence, normal force, compliance of the rubber, and cloth friction grow; energy loss jumps and the outbound line opens up (what players call “banking long”). Throw from side-spin and friction at the nose can also bend the rebound a few degrees.

Two levers dominate: contact height (nose height vs. ball center) and effective stiffness (rubber + facing + backing). Lower noses reduce downward compression and often produce zippy, shorter banks; higher noses drive the ball down into cloth, adding friction and stretching the outbound path.

Specs that actually matter (with numbers)

- WPA cushion nose height: 63.5% ± 1% of ball diameter. For 2¼" balls, target ≈ 36.3 mm (≈ 1 7/16"). Measure from the slate plane to the cushion nose—not the cloth.

- Cloth-covered cushion width: 1⅞–2.0" from featherstrip to nose to keep ball contact in the sweet zone along the profile.

- Pocket facings: 1/16–¼" allowed; aim for 1/8". Facings should be harder than the cushion so jaws don’t “eat” speed on near-misses.

-

Premium cushion examples:

- Klematch P59 — Shore A 43 ± 3, rebound ~75% ± 5% (lively but controlled).

- Artemis K-66 — Shore A ~40 ± 5, rebound ~72% ± 5% (classic pool feel).

Use these numbers to sanity-check parts and installs. If your rails feel wrong, confirm geometry before swapping rubber.

Why one brand (or table) banks different than another

1) Nose height & angle

A few millimeters high or low changes the vertical contact patch and down-force into the cloth. Lower noses typically feel quicker and bank shorter. Higher noses drive longer, slower banks and can magnify roll-off on soft shots.

2) Rubber profile & compound

K-66 is the modern pool standard; K-55 is taller/deeper on some classics. The geometry decides where the ball meets the nose through a range of speeds; the compound decides how efficiently that collision returns speed and angle. Softer compounds can feel springy at soft-to-medium speeds; very hard compounds can reflect angles beautifully but punish bad facings and loose bolts with clang and skid.

3) Cloth, balls & environment

New worsted cloth has lower pile height and lower friction. Combine that with polished balls and dry air, and banks shorten. In humid rooms, cloth grabs—the same line hits longer and speed bleeds earlier. It’s not your imagination; the delta can be several inches on common 1-rail banks.

4) Installation & aging

Rail build-ups that aren’t flat, weak glue bonds between rubber and rail wood, mismatched facing thickness, and sloppy torque make rails inconsistent along their length. Heavy rooms add compression set over time, changing feel month to month.

How to test a table (simple & repeatable)

- Lag lengths. Center-ball up and back down the middle. Healthy tournament cushions yield ~4–4.5 table lengths without hopping. Log results per table for apples-to-apples comparisons.

- Mirror-bank calibration. Use a basic mirror system on standard 1-rail banks at medium speed. If everything trends short/long, check nose height and cloth condition first.

- Jaw behavior. Fire soft to medium shots near both pocket jaws. Excess grab = soft facings or over-thick shims; loud ring + kickouts = hard facings or loose rails.

- Sound + feel. A hollow “thunk” along one section suggests bond separation. A sharp “clang” at all speeds suggests torque/facing mismatch.

Diagnose & fix (in this order)

- Measure nose height every ~8–10" on each rail. Target ≈ 1 7/16" (36.3 mm) for 2¼" balls; keep variance within ±1 mm.

- Verify facings are matched left/right and sit flat. Prefer 1/8" thickness; compound harder than the cushion.

- Torque correctly. Follow your model’s sheet with a calibrated wrench. Uneven torque = uneven energy return.

- Re-bond delaminations. Any gap between rubber and rail wood is a dead spot—remove, clean, re-glue, clamp properly.

- Reset the friction baseline. Tighten/iron cloth, clean and polish balls, control humidity. Retest banks before blaming rubber.

- Upgrade cushions last. Once geometry and install are right, then choose compound/profile to taste.

FAQ

Do “harder” cushions always bank shorter?

No. Durometer is one piece. Nose height, facing spec, cloth friction, and impact angle drive the result. Fix geometry and facings first; then judge the rubber.

Why did my table bank differently after a recover?

Fresh, tight worsted cloth + polished balls drop friction, so banks often run shorter. If it also feels springy or inconsistent, check nose height and facing thickness before touching the cushions.

Why do some Diamond tables feel fast and bank short?

It’s a combo of cushion action and nose geometry. They’re famous for it. Once you understand the bias, you’ll aim accordingly and score more.

What’s the fastest way to tell if a rail is “dead”?

Listen and log. If the sound dulls and the rebound distance drops only on one segment, suspect a bond issue or local nose-height error rather than bad rubber.

Can I fix long banks without replacing cushions?

Often, yes. Correct the nose height, standardize facings to 1/8", set proper torque, and reset the friction baseline. Re-test before buying new rubber.

References

- WPA, Recommended Equipment Specifications (2024) — cushion nose height 63.5%±1%, cushion width, facings thickness & hardness, and 4–4.5 length speed check.

- Dr. Dave, Cushion Nose Height FAQ; Diamond Brand Tables; Cloth Effects; Cushion Rebound Efficiency.

- Klematch, P59 Technical Datasheet — Shore A 43±3, rebound ~75%±5%.

- Artemis (distributor listings), e.g. K-66 rubber specs — Shore A ~40±5, rebound ~72%±5%.

- Valley-Dynamo, Cushion Rail Facts & Tips — example torque guidance (~65 in-lb) for standard cushion rails.

- Diamond (example owner sheet), Smart/Pro-Am quick reference — top assembly bolt torque 20–25 ft-lb (model-dependent).