Enjoy our modern designs

Estimated Read Time: 6 mins |

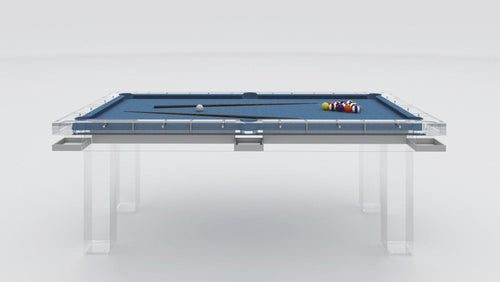

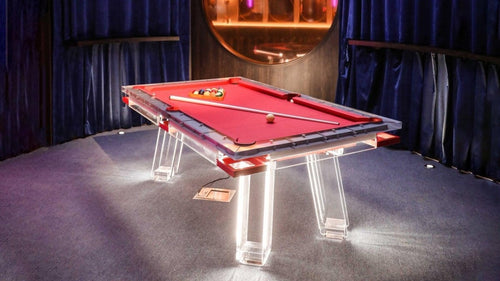

Lucite—chemically known as PMMA—has a reputation for eye‑catching clarity, but durability matters just as much when you’re building a piece meant for daily use. Here’s a focused walk‑through of the material’s strengths, limitations, and care requirements—each point builds on the last, so you’ll know exactly where Lucite shines and where it needs backup.

Mechanical Strength & Stiffness

Lucite’s tensile strength is 55–75 MPa, with a Young’s modulus around 3 GPa. It’s strong enough for furniture, but bends far more than hardwood or steel. Keep those flex numbers in mind—every later topic ties back to them.

Impact Toughness

Lucite is about 17× more shatter‑resistant than glass. It’s not polycarbonate, but shrugs off normal household knocks and dropped cues without spider‑cracking.

Surface Hardness & Scratch Resistance

Lucite rates about 4H on the pencil‑hardness scale—harder than most clear plastics. It keeps a high‑gloss finish, but hairline scratches accumulate with use. Polish and hard‑coats can restore/upgrade the surface.

Weather & UV Stability

UV‑stable Lucite stays clear for decades—outdoor furniture can last 10–30 years before any yellowing or haze. Durability is about both breakage and long‑term looks.

Chemical Resistance & Stress Cracking

Lucite handles mild detergents, oils, and dilute acids, but alcohol‑based sprays or ketone solvents can trigger micro‑cracks (especially where sheets are stressed or flexed). Use neutral, gentle cleaners to avoid “crazing.”

Creep & Long‑Term Load Limits

Lucite can sag over time if loaded beyond about 5–10 MPa. Furniture builders use thicker sections or hidden metal spines to keep rigidity long‑term.

Thermal Behavior

Lucite softens near 100 °C and expands ~6× more than steel. Use oversized mounting holes and gaskets to prevent thermal stress and surface cracks.

Routine Maintenance

- Clean with mild soap and microfiber—never ammonia or alcohol wipes.

- Polish hairline scratches with plastic polish; deeper marks can be sanded and buffed.

- Apply clear hard‑coat every few years for high‑wear zones.

- Inspect joints annually; stress from fasteners can show up later as surface crazing.

9. Lucite vs. Glass vs. Polycarbonate (Quick Reference)

| Property | Lucite | Glass | Polycarbonate |

|---|---|---|---|

| Light transmission | 92 % | 89–90 % | 88 % |

| Impact toughness | 17× glass | Baseline | 250× glass |

| Scratch hardness | 4H | 6–7H | 2–3H |

| UV stability | High | Very high | Needs coating |

| Continuous stress limit | 5–10 MPa | 25–30 MPa | 10–15 MPa |

The table brings everything together: Lucite beats glass on impact but trails it in scratch hardness, and it sits comfortably between glass and polycarbonate on overall durability.

Key Takeaways

- Balanced durability: strong, reasonably stiff, and dramatically tougher than glass—good for statement pieces.

- Surface integrity: natural 4H hardness is scratch‑resistant enough for daily use; hard‑coat upgrades are easy.

- Long‑term clarity: UV‑stable grades stay clear for decades, making outdoor installs realistic.

- Chemical caution: alcohols and ketones cause crazing—stick to neutral cleaners.

- Design smart: limit continuous stress to 5–10 MPa and allow for thermal expansion; add hidden reinforcements when zero sag is mandatory.