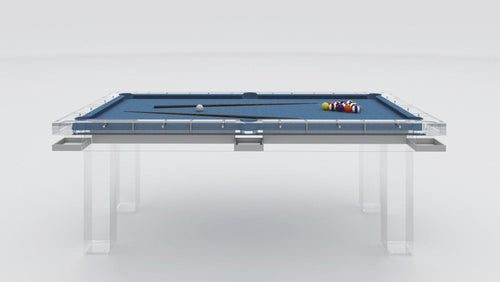

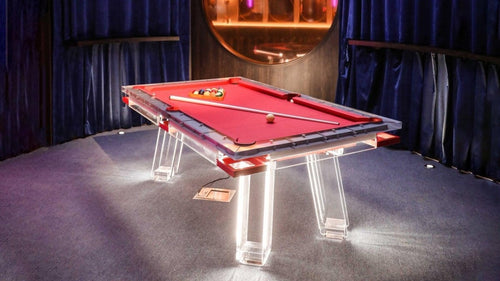

Enjoy our modern designs

Estimated Read Time: 6 mins | Updated:

Pool (or billiards) wouldn’t be the same game without its most iconic elements: the pool balls. While these smooth, polished spheres may appear simple, they’re the result of centuries of innovation. From wooden origins to modern plastics, various materials have been tried—some even exploded during play! Below, we’ll explore what a pool ball is made of, delve into the fascinating history, and see why certain materials became the industry standard.

Modern Pool Balls: Phenolic Resin vs. Polyester

Today, most pool balls are made using phenolic resin or polyester resin.

- Phenolic Resin: The top choice for professional-grade sets, phenolic resin is a thermosetting plastic known for its hardness, consistency, and ability to withstand hundreds of thousands of high-impact hits without cracking. Aramith is a famous brand using this resin, and phenolic sets can last for decades—often up to 40 years.

- Polyester Resin: A more budget-friendly material with decent durability. Polyester balls are perfect for beginners or casual play, though they wear faster (around 8 years of steady use).

Phenolic resin retains its shine and smooth surface far longer than polyester, ensuring consistent roll and rebound. That’s why most professional tournaments and leagues rely on phenolic sets.

A Brief History of Pool Ball Materials

The evolution of pool ball materials directly mirrors the growth of the game itself. Early forms of billiards trace back to lawn games in 15th- and 16th-century Europe, and the earliest “billiard balls” were simply made of wood.

Ivory: Elegance with a Cost

By the 17th century, high society preferred ivory balls carved from elephant tusks. Though elegant, they were expensive, inconsistent in quality, and contributed to the overhunting of elephants—making ivory increasingly rare and controversial.

The Search for Alternatives: Celluloid and Beyond

As ivory became unsustainable, manufacturers offered rewards for new materials. John Wesley Hyatt famously introduced celluloid, an early plastic, but it had a dangerous tendency to explode under heat and pressure. Despite that, his innovation paved the way for other plastics like Bakelite, invented in 1907 by Leo Baekeland, which offered greater stability and durability.

Phenolic Resin Takes Over

By the mid-20th century, phenolic resin emerged as the gold standard due to its exceptional impact resistance and uniform density. Saluc (makers of Aramith) refined phenolic resin manufacturing, producing balls so durable they can endure up to 400,000 impacts. Today, this remains the material of choice for professionals.

Why Phenolic Resin Reigns Supreme

Phenolic resin’s popularity isn’t just about durability—it’s also about consistency. Each ball is formed under extreme pressure, resulting in uniform color throughout (no paint layers to chip off) and consistent weight distribution. The finished spheres are highly polished, ensuring minimal friction against the felt and accurate rebounds off cushions.

Key Benefits:

- Longevity: Lasts multiple times longer than polyester and retains its glossy finish.

- Consistency: Precise weight and balance control, vital for competitive play.

- Heat Resistance: Heat from friction won’t distort or damage the balls.

Other Materials: Are They Still Used?

Aside from phenolic resin and polyester resin, you might encounter epoxy resin in experimental sets or novelty balls with custom designs. While epoxy shows promise in various industries (like countertops and flooring), it hasn’t overtaken phenolic resin for standard billiard production due to cost and performance constraints.

As for ivory and wood, these remain historical curiosities or collector’s items rather than modern-day gaming essentials.

Environmental and Ethical Shifts

One silver lining of the industry’s move to plastics is the protection of wildlife, especially elephants. Ivory’s decline drastically reduced the need for poaching in this context. Though plastics come with their own environmental footprint, many billiard ball manufacturers now work to minimize waste and explore more eco-friendly production methods.

Conclusion

From exploding celluloid to robust phenolic resin, billiard balls have come a long way. When someone asks, “What is a pool ball made of?” the modern answer is usually phenolic resin or polyester resin—each offering a unique balance of durability, cost, and playing characteristics.

Whether you’re an enthusiastic amateur or a serious competitor, investing in a durable set of billiard balls is crucial for consistent, enjoyable gameplay—so chalk up, break, and enjoy the game with a new sense of respect for the engineering behind every ball.